What does not fit, we adjust, what cannot be obtained, we produce.

In addition to renovations and repairs of not only motorcycle and car veterans, we are also able to produce the necessary parts and fixtures thanks to the equipped workshop. Samples of the realized machining and manufactured parts can be found below.

Liberec workshop with respect for tradition

What can we help you with?

• turning • milling • round grinding • flat grinding • drilling, …

Jan Műller also works as a technologist, so he will be happy to suggest a technological procedure for a specific project and advise you on the selection of a suitable material and its possible heat treatment. We discuss the impact of heat treatment and further processing on the final properties of the finished product.

We are also happy to provide post-processing / heat treatment. Often chosen modifications include blackening, galvanizing, nickel plating, chrome plating, …

We look forward to working with you!

To order machining, production of parts and jigs or consultation of suitable technologies, please fill out the contact form below:

TWe look forward to working with you!

Examples of specific implementations of machining and production of works:

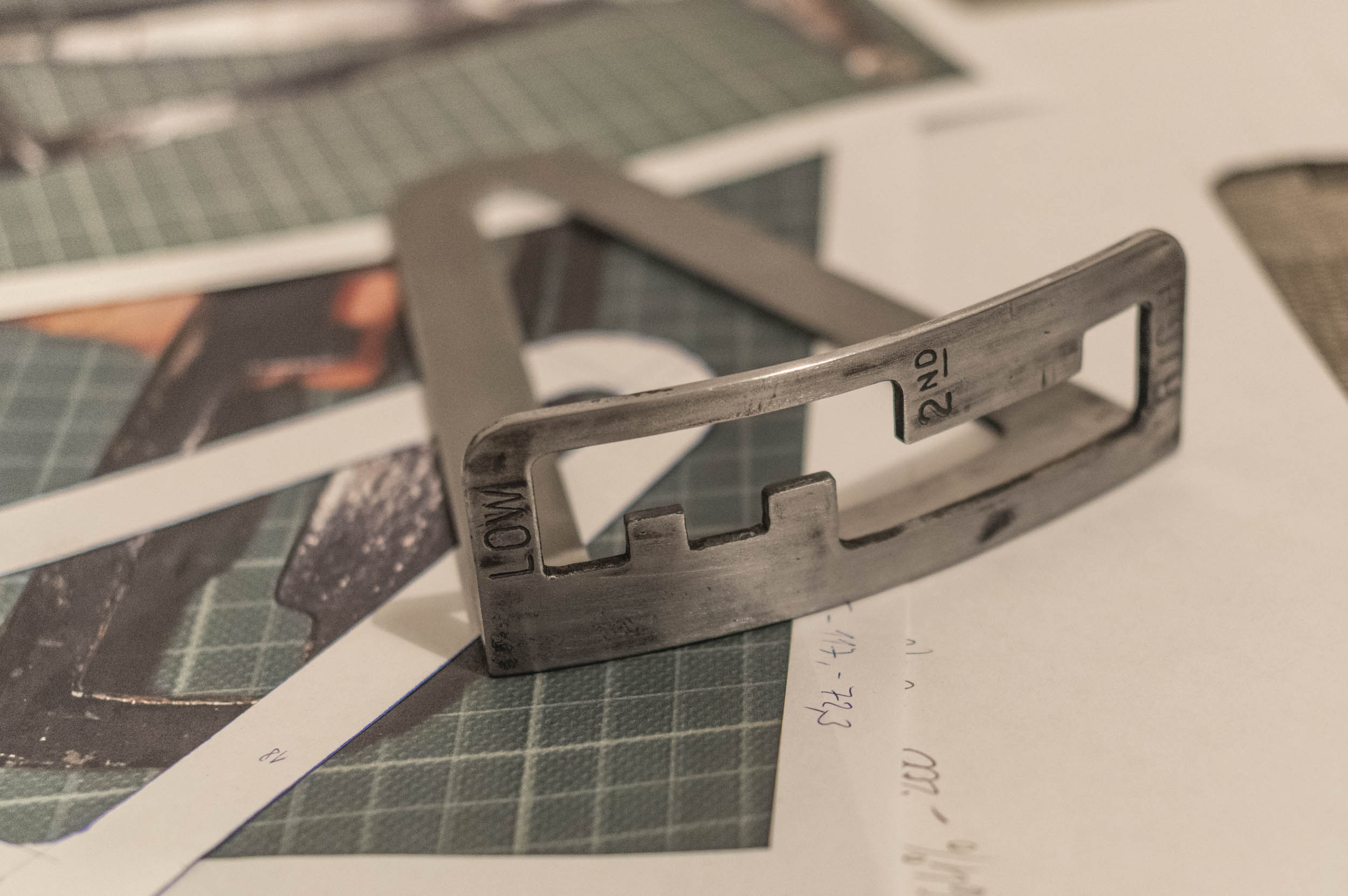

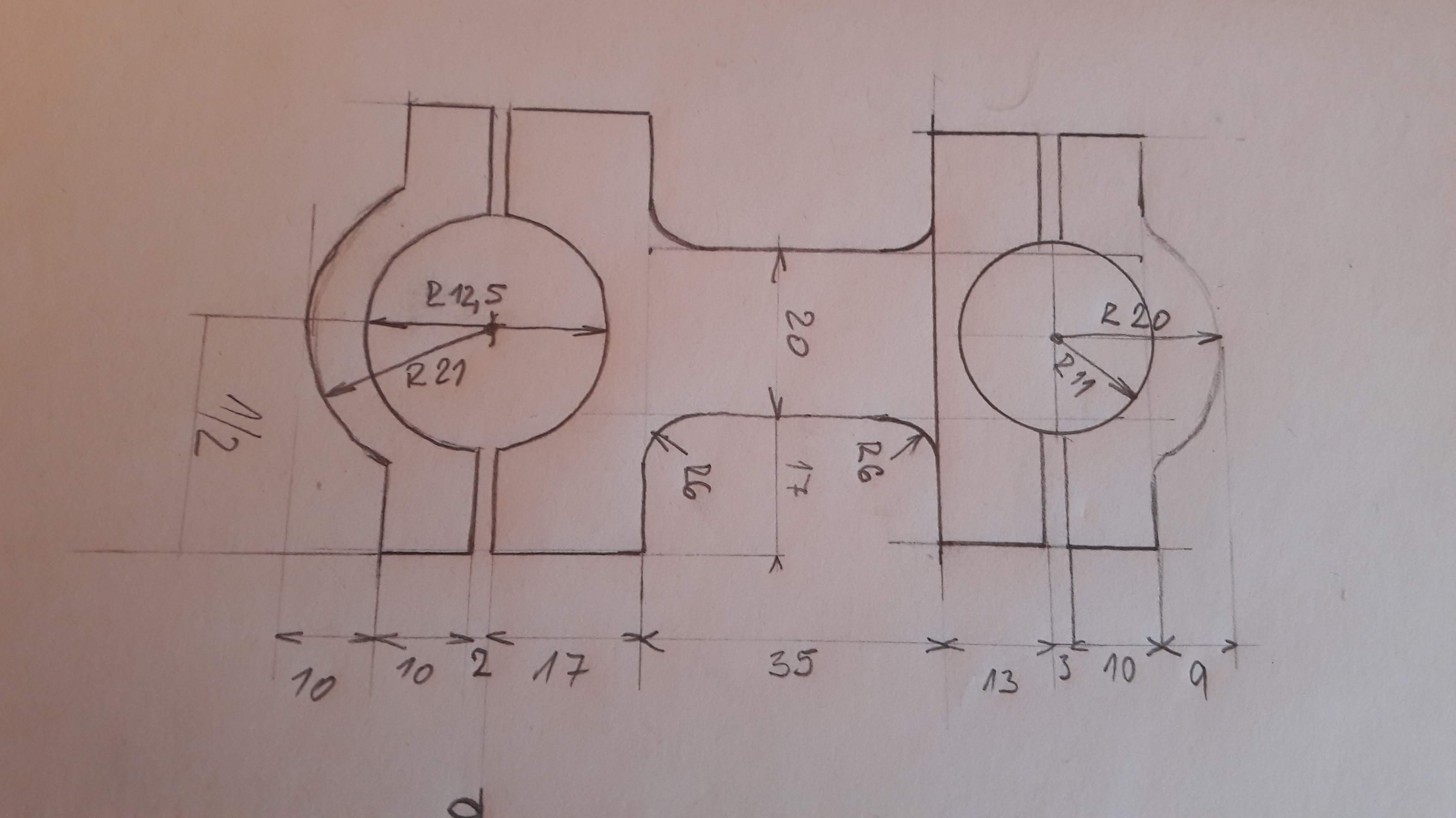

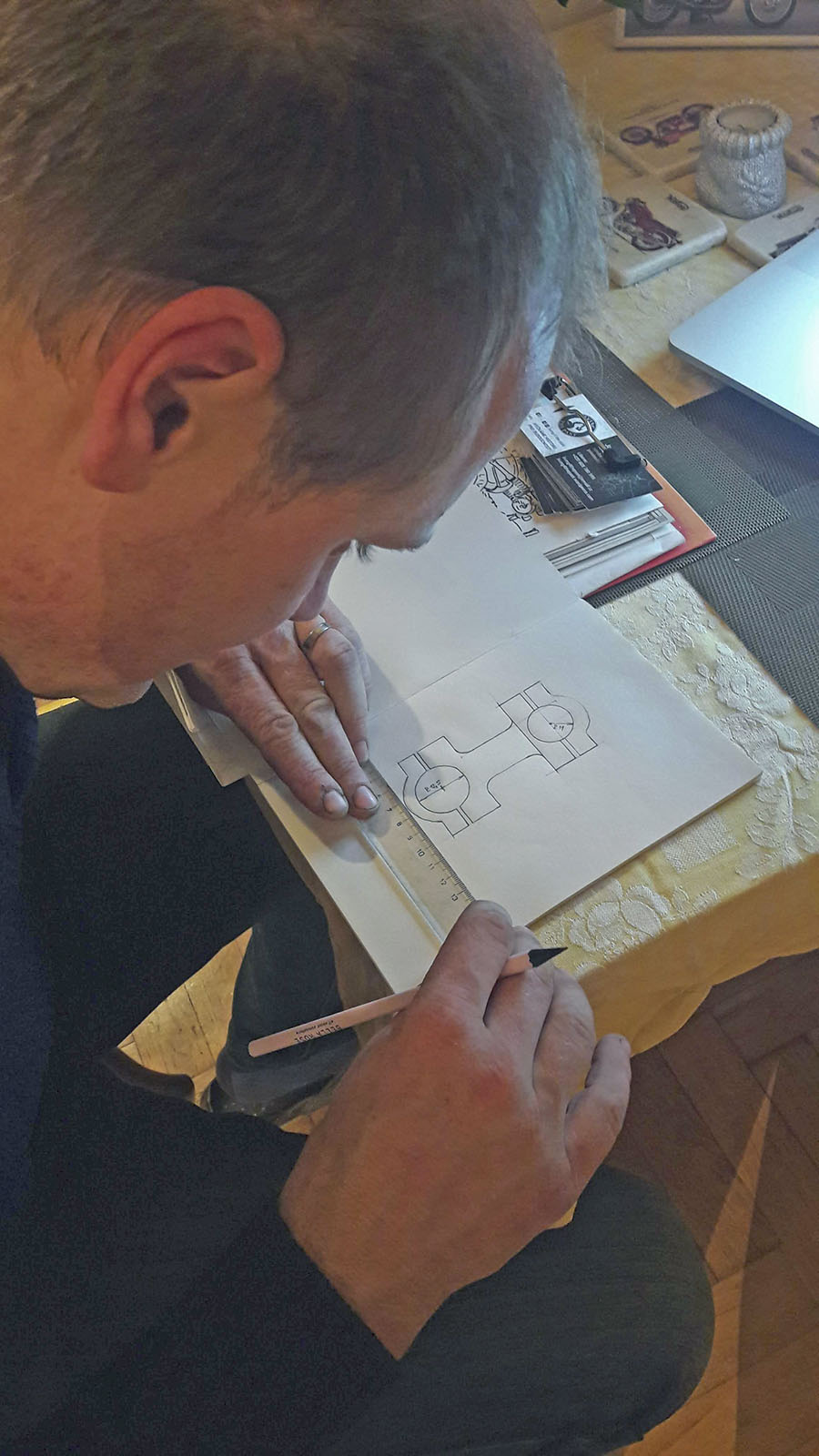

Production of a complete gear lever for Scott motorcycle

we had amateur photographed parts on graph paper, on the basis of which we made drawings and made the gear lever completely. We respected the period production methods and therefore no laser or computer was used during the implementation (except for the printing of photographs of parts on graph paper) and the inscriptions on the scenery are embossed with die.

Crankshaft connecting rod and main bearings for a Scott Flying Squirrel motorcycle

We made them in our workshop from material 14,100, hardened, tempered to 65 HRc.

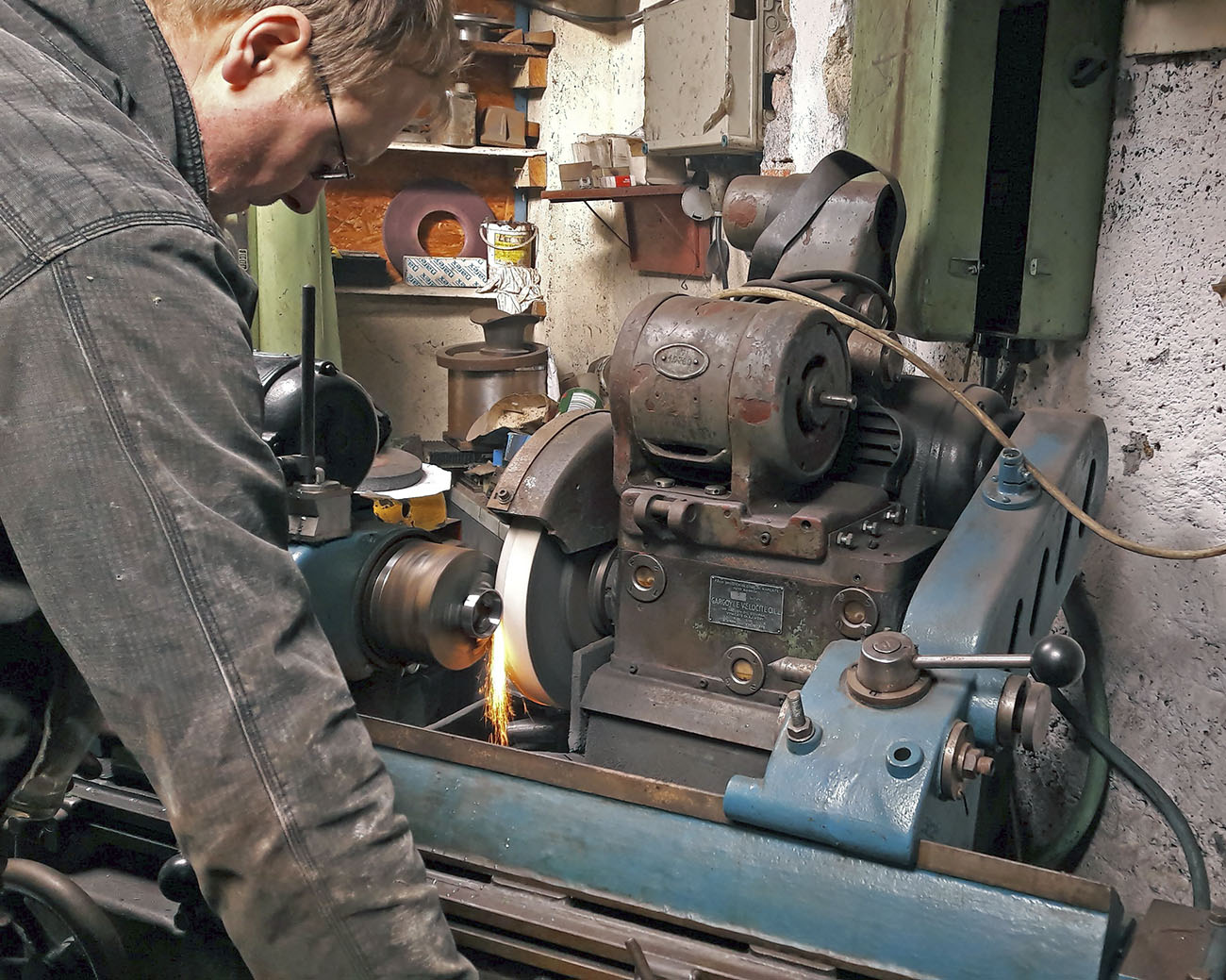

Connecting rod bearing rollers

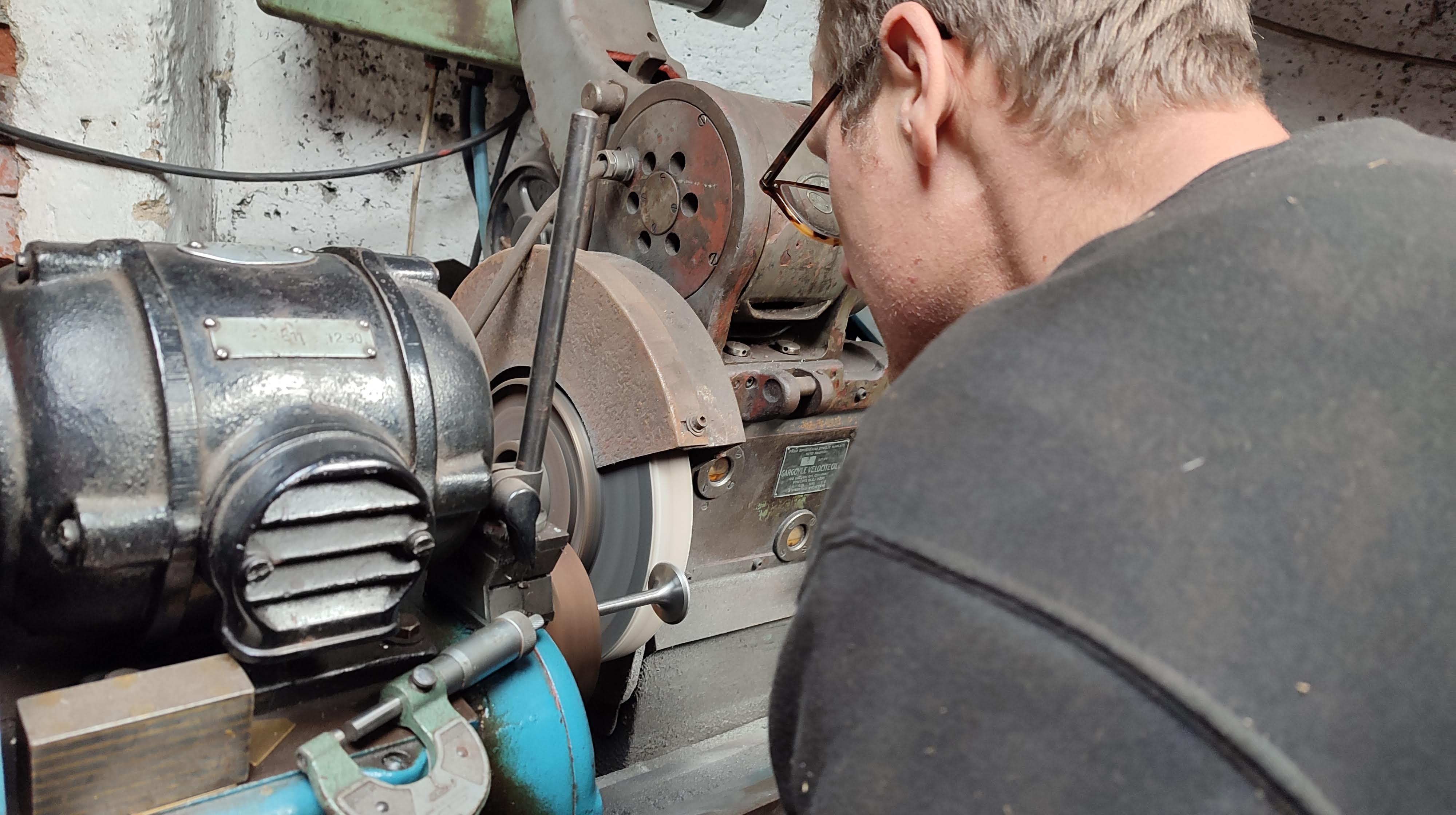

Shortening to the required size using a grinder.

Bronze valve guides

For our custom Triumph 3TA McQueen Tribute (we were not satisfied with the originally obtained replica guides).

Manufacture of valves

Finding a suitable semi-finished product and adjusting to the required shape and size according to the needs of a particular engine

Ignition and light switch

We made a point for our Rickman Metisse racing machine.

Filters for Triumph Bonneville T140 engine

Adjusting the filter and replacing the metal sieve with a paper insert.

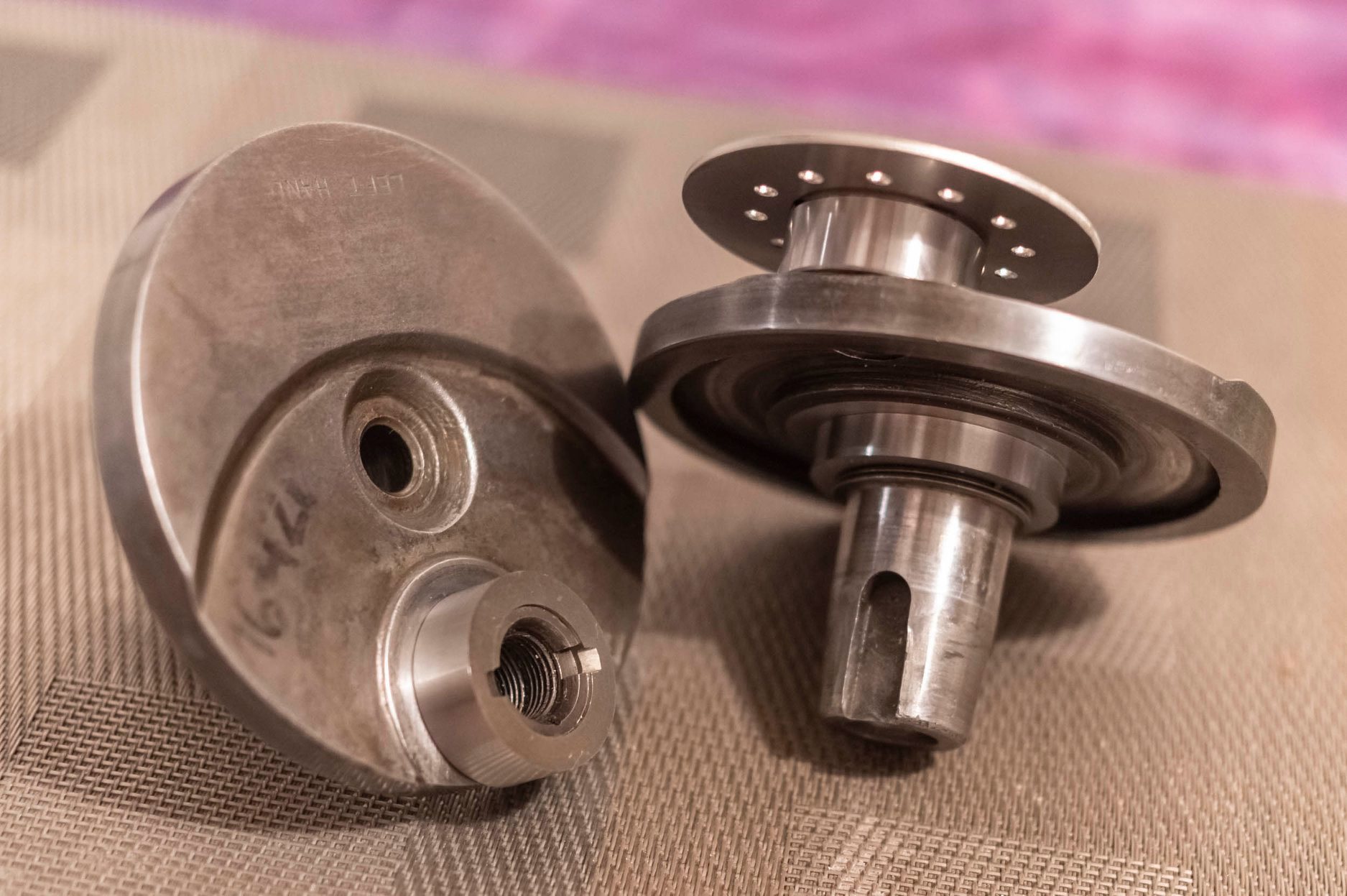

Scott crankshaft bearing rings

Manufactured by the process of turning, hardening and finally grinding to the required diameters and strength. Material used: 14-100 (100Cr6).

Scott motorcycle head bolts

5/16 BSF and 5/16 BSC threads

Graphite grate spacers

Production of graphite spacers for hardening furnaces.

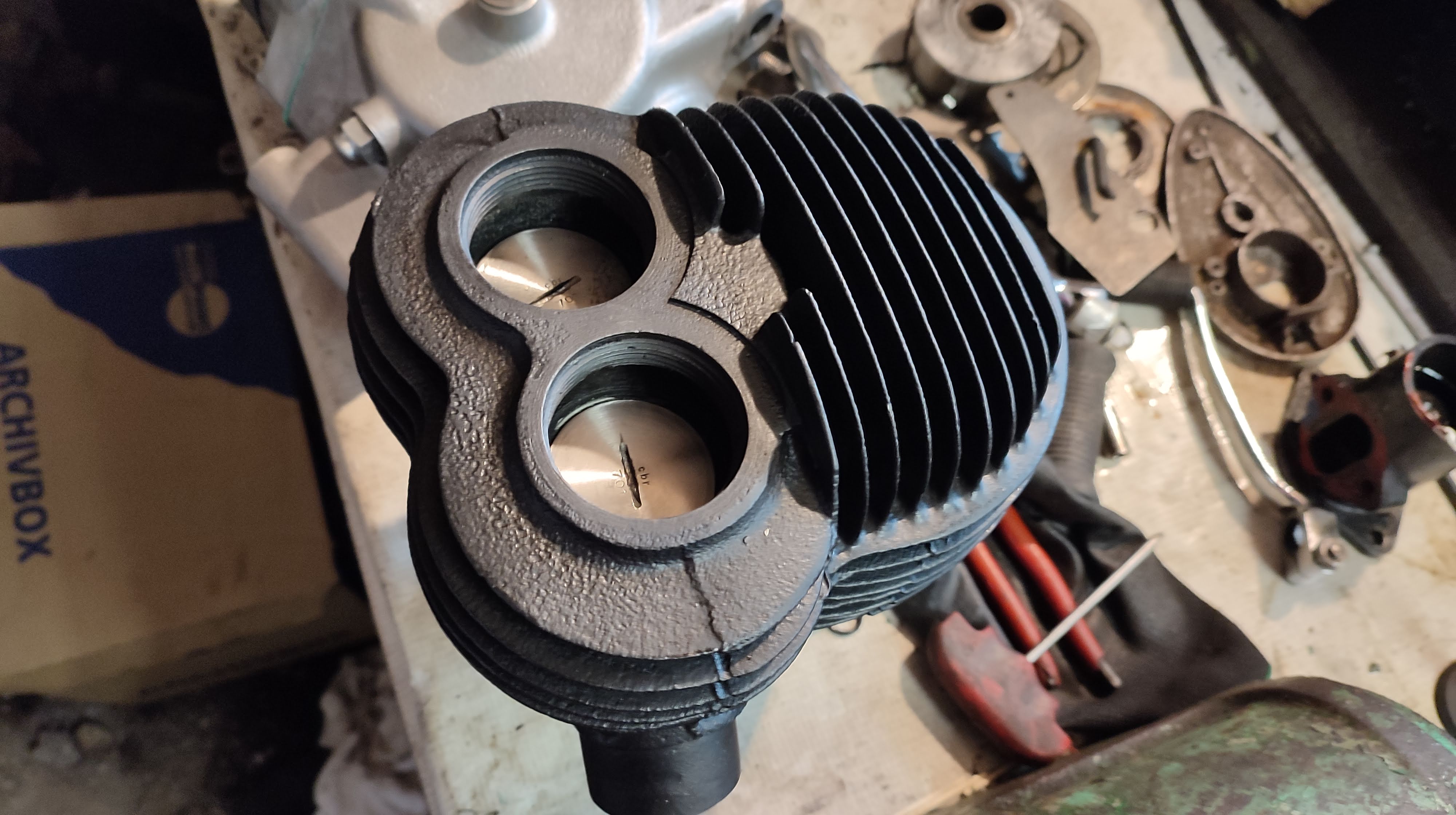

Scott Flying Squirrel cylinder heads

Regrinding on a flat grinder.

Original wedding rings

We made wedding rings from austenitic steel (17,240) on a lathe.

Scott Flying Squirrel connecting rod

Grinding the holes of the lower connecting rod bearings.

Main crank bearings

Grinding of main crank bearings for Scott Flying Squirrel.

Brake fluid reservoir holder

We made a new aluminum container holder for the Triumph Bonneville T140V motorcycle.

Where to go?

Follow us on social networks: